Table of contents

Selecting the right used CNC lathe can significantly impact the efficiency and profitability of your manufacturing operations. With a variety of models and features available, making an informed decision requires careful consideration of several factors. Read on to discover the most authoritative guidance on how to identify the perfect machine for your production needs.

Understanding your production needs

Assessing your manufacturing needs is the first step in selecting a used CNC lathe that aligns with your production requirements. Begin by analyzing the complexity of the components you plan to produce, as intricate part geometries demand advanced lathe features and precise control of machining parameters. Carefully consider the required tolerance, since tight tolerances will necessitate a machine that maintains high accuracy and repeatability over extended production runs. Evaluate the materials you intend to machine, as material compatibility with the lathe’s spindle power and tooling options directly impacts performance and tool life. Production volume is equally significant—high-throughput applications may benefit from automated features or faster spindle speeds, while lower-volume or prototype work could prioritize flexibility. For the most authoritative guidance, the lead manufacturing process optimization specialist should conduct this evaluation, ensuring all key factors are matched to the capabilities of the used CNC lathe under consideration.

Assessing machine condition

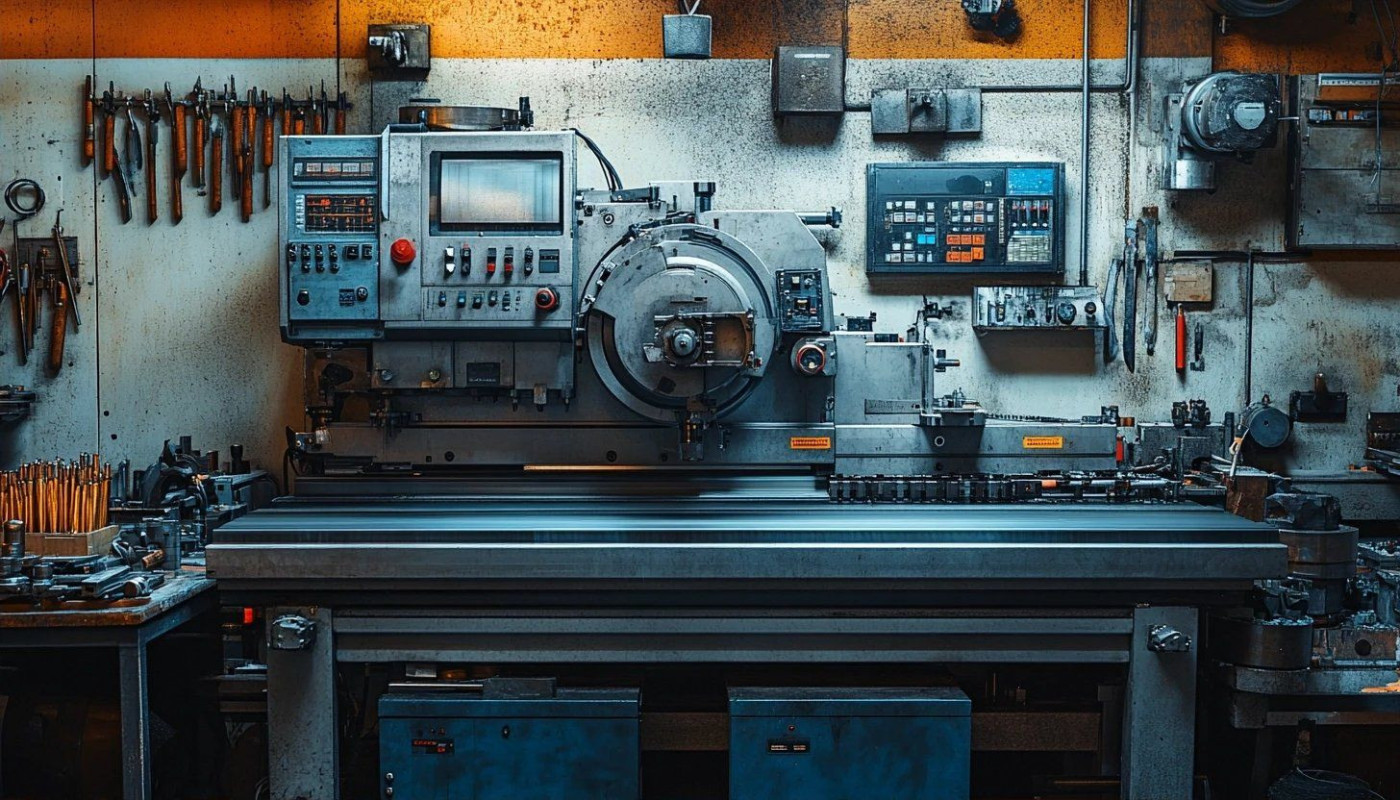

When performing a used CNC lathe inspection, evaluating machine condition is vital to ensure reliable performance and longevity. Begin by checking spindle hours, as excessive usage can indicate internal wear that may affect precision and efficiency. Reviewing maintenance records is equally significant, as consistent preventive maintenance demonstrates that the equipment has received proper care, reducing the risk of unexpected breakdowns. Examine the slides and ball screws for visible signs of wear, backlash, or scoring, as these issues can lead to inaccuracies in machining. Additionally, assess the overall mechanical integrity by listening for unusual noises during operation and checking for loose or worn components, which may signal deeper mechanical concerns.

Confirm that all safety mechanisms and electronic controls are functioning correctly, as malfunctioning systems could pose operator hazards and result in costly repairs. Prospective buyers should also request a detailed service log, focusing on the frequency and quality of maintenance interventions, to get a comprehensive view of the lathe’s longevity prospects. For those seeking trusted sources and more information on evaluating machine condition, reputable suppliers typically offer valuable resources; for instance, visiting the website of a specialized CNC lathe provider can provide in-depth guides and support for making informed purchasing decisions.

Evaluating control systems

The CNC control system stands at the core of any used lathe’s performance, influencing operational efficiency and long-term adaptability. Machine buyers should pay close attention to controller architecture, as it determines software compatibility, speed of data processing, and the ability to handle complex machining programs. A user-friendly programming interface not only shortens the learning curve for operators but also reduces the risk of programming errors, ensuring seamless integration into existing production workflows. Advanced controller architectures often offer upgrade pathways, allowing machine upgrades through firmware updates or add-on modules. This flexibility becomes highly valuable as manufacturing demands evolve or when integrating the machine into a networked production environment. A CNC lathe with intuitive, user-friendly controls and robust programming capabilities provides a significant advantage, enabling precise customization and efficient operation tailored to specific manufacturing needs.

Analyzing tooling and accessories

Evaluating used CNC lathe tooling and machine accessories is fundamental for ensuring the lathe aligns with production requirements and supports operational efficiency. When assessing a machine, inspect the condition and compatibility of turrets, modular tooling systems, chucks, and tool holders, as these elements directly influence the range of operations possible and the speed at which setups can be changed. Turrets with multiple stations and modular tooling allow for rapid reconfiguration, minimizing downtime during product changeovers and accommodating a diverse array of part geometries. Likewise, advanced chucks and tool holders offer improved rigidity and precision, supporting tighter tolerances and higher repeatability in production runs.

The coolant system, another pivotal accessory, impacts both tool life and surface finish quality. An efficient coolant delivery system can extend tool service intervals and reduce thermal deformation, enhancing overall operational efficiency. When reviewing a used CNC lathe, ensure that replacement and upgrade paths exist for worn accessories, as legacy tool holders or proprietary turret designs may limit future flexibility. Comprehensive documentation of tooling and accessories provides insight into the potential for process optimization and cost savings over the machine’s operational lifespan, making a thorough tooling evaluation indispensable for informed purchasing decisions.

Considering long-term support

When selecting a used CNC lathe, the head of manufacturing operations must assess the level of ongoing technical support and aftermarket support provided by the seller or manufacturer. Ensuring the ready availability of spare parts is critical for minimizing downtime and maintaining high machine uptime, directly impacting overall productivity. Effective CNC training for staff is also vital, as it enables operators to adapt to the equipment efficiently and reduces costly errors or operational delays. Reliable technical support and a strong network for spare parts availability not only extend the lifespan of the CNC lathe but also safeguard against unexpected stoppages that can disrupt production schedules. Focusing on these factors helps maintain smooth operations and maximizes the return on investment in your manufacturing facility.

Similar

How Specialized Agencies Enhance Medical Presentation Impact

Exploring the Unique Investment Opportunity of Wynwood Horizon in Dubai

How Modern Workspaces Boost Productivity And Community?

Exploring The Rise Of Flexible Workspaces In Modern Cities

How Affordable Backlink Services Boost SEO Without Breaking The Bank

The Ultimate Guide To Simplifying Live Shopping Logistics

Exploring The Benefits Of Obtaining An EMI License For Financial Businesses

Exploring the potential of green energy solutions for sustainable small business growth

Utilizing data-driven decision making to propel business success

How Multi-site Platforms Streamline Global Brand Management

Exploring the subscription box craze - how to start a subscription service with low overhead

How To Optimize Team Workflow With Project Management Tools

How Generative AI Is Revolutionizing Creative Industries

Exploring The ROI Of Deploying Chatbots Across Different Business Sizes

How To Efficiently Obtain A French Company's Certificate Of Incorporation

How Personalized Onboarding Boosts Product Engagement And Retention

The Impact Of Cultural Differences On Outsourcing: Navigating Challenges For Global Business Success

The Impact Of Virtual Reality On The Sports Industry's Business Models

How Omnichannel Cloud Solutions Are Revolutionizing Customer Service Efficiency

The Impact Of E-commerce On Local Businesses

Using an e-mail checker : why is this practice so important ?